Grinding dust extraction machine is an equipment used to effectively absorb the dust generated during grinding operations and improve the air quality in the workplace. Such machines are often used in industrial workshops, carpentry workshops or metalworking plants. Here is some general information about grinding dust extraction machine:

Function: Grinding dust extraction machines improve the ambient air quality by absorbing dust and particles generated during grinding operations. This has a positive effect on worker health and creates a safer working environment in the workplace.

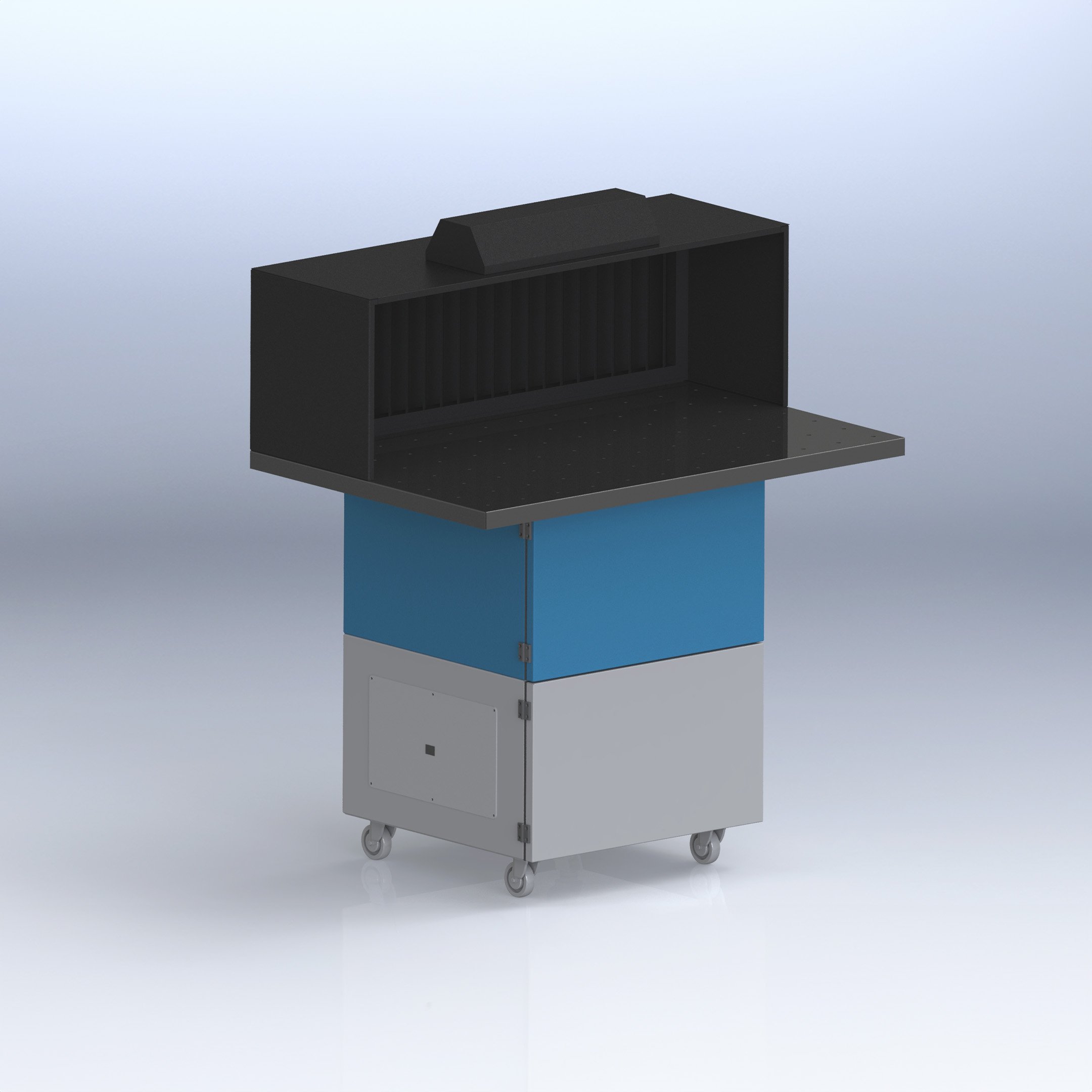

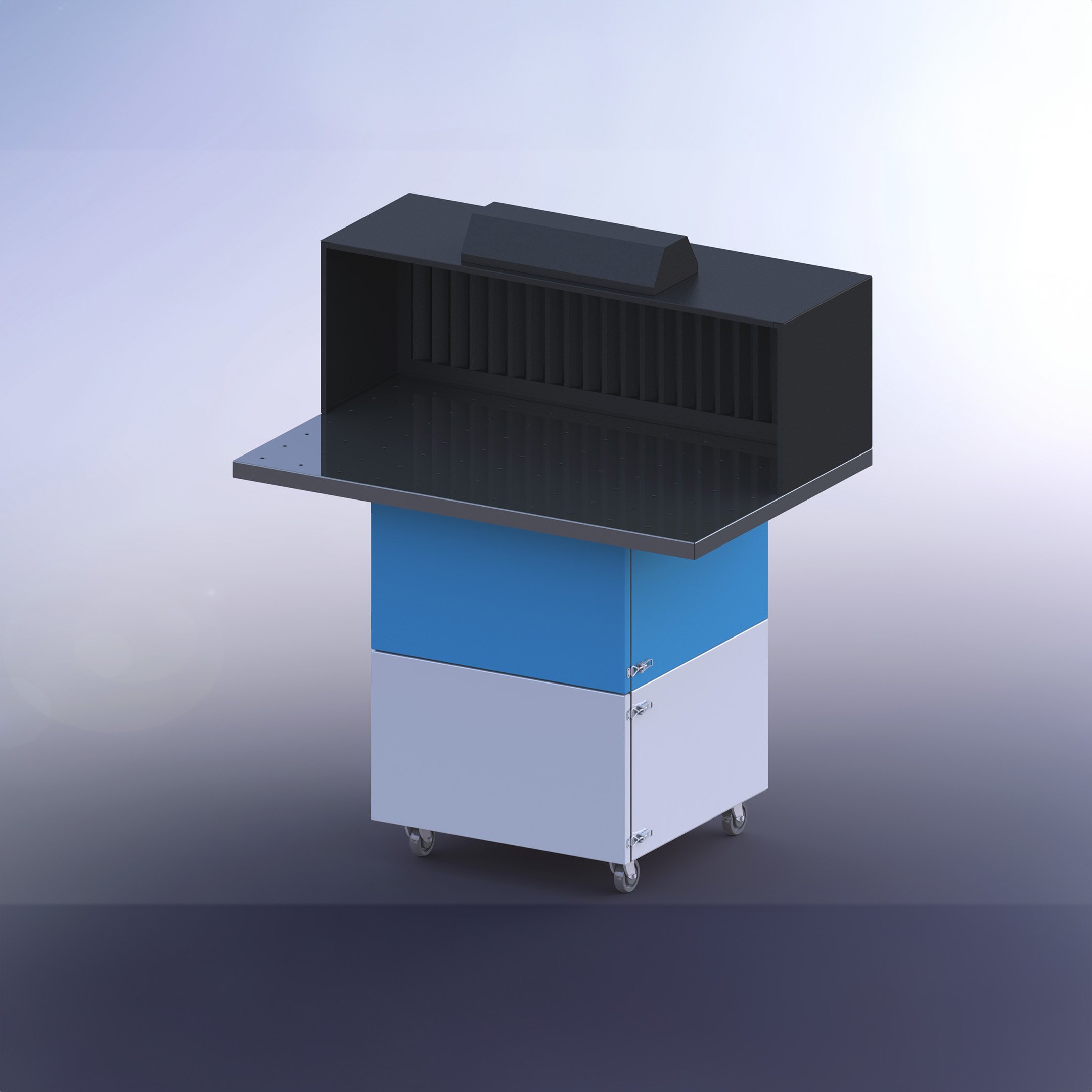

Structure: The machines, which usually have a metal frame, are equipped with a suction system. This suction system is designed to collect and filter the dust generated during the grinding process.

Filtering System: High-performance filters are usually used to effectively filter the dust. These filters have the capacity to hold particulate matter to improve air quality.

Adjustment and Portability: Many grinding dust extraction machines are height adjustable and equipped with wheels, making the machine portable and user friendly.

Suction Power and Capacity: The suction power and dust capacity of the machine may vary depending on the process and workplace to be used. These features can have an impact on the efficiency and effectiveness of the table.

Safety Features: It is important to take safety precautions during the use of grinding dust extraction machines. Therefore, the design of the machine should include safety features necessary for user safety.

Maintenance and Cleaning: Regular maintenance of the machine and timely replacement of filters ensures long life of the table and maintains an effective dust extraction performance.

When selecting a grinding dust extraction machine, it is important to consider the material and processing characteristics to be used. It is also important to check compliance with local occupational health and safety regulations.